Mechanical Condition Fault Simulator for Education and Training Purposes

Mechanical Condition Fault Simulator for Education and Training Purposes

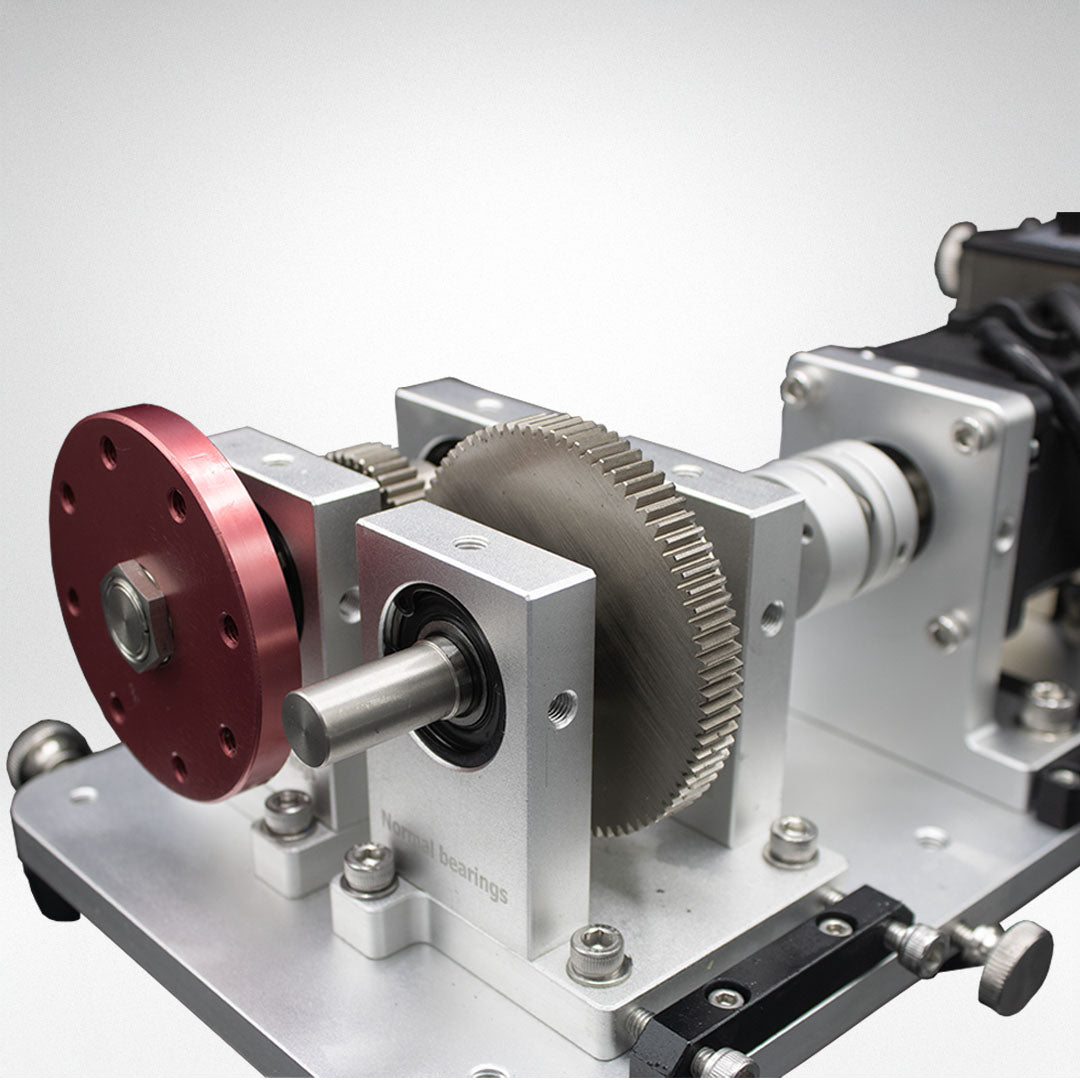

This experimental platform can simulate the fault states in shafts, bearings, rotors and their bases.

Approximately 80% of the equipment is made of high-strength aluminum alloy, which greatly reduces the

weight of the equipment while ensuring its strength, making it easy to transport. The surface has been

treated physically and chemically to enhance the machine’s appearance. This equipment is widely used in

scientific research, teaching, product development, personnel training, and participating in exhibitions in

universities, industrial and mining industries, and research institutions.

1. Can simulate fault characteristics of shafts, bearings, and other components at various speeds,

with an adjustable range from 0 to 3000 RPM.

2. The shaft assembly can simulate shaft angle misalignment, mass imbalance, loose mounting

base, and bearing failure.

The bearing faults that can be simulated include cracks in the inner ring, damage to the outer ring,

defects in the bearing balls, combined bearing faults, and fractures in the retainer.

The EI-TSIM4 vibration testing platform consists of a drive motor, drive shaft, driven shaft, large gear,

small gear, bearing seat, rotor, foundation base, backlash adjustment screw, and motor controller.

Couldn't load pickup availability

Share